At present, China's robot industry construction is in a period of great change. While the speed of industrial development is accelerating, China's robots are also facing changes in technology and quality. This means that we can no longer rely solely on capacity and price competition, but to have a place in the international arena to create brand influence and quality.

Currently, robots are stepping up their production lines to “invade†Chinese factories. Along with this market with unlimited potential, the robot industry has also entered the “golden ageâ€. Enterprises, capital and government have focused on the robot industry, and a “robot war†is kicking off. Looking at the world, in recent years, the robot industry has become the commanding height of competition among countries. In the 13th Five-Year Plan, China has also listed robots as an emerging frontier that can vigorously promote innovation and industrialization.

The pioneer of "Made in China 2025"

The robot industry is the first industry to achieve breakthroughs in the construction of “Made in China 2025â€, which is benefited from the rigid demand for industrial upgrading in China. With the rising labor costs, the profits of enterprises have shrunk greatly, and with the depreciation of the RMB, the profits of a large number of export processing enterprises have been negligible. It is the only way for China's manufacturing industry to achieve industrial upgrading through intelligent manufacturing, thereby improving efficiency and reducing costs.

According to a report released by market research firm IDC on China's industrial robots, by 2018, China's manufacturing robot adoption rate is expected to grow by more than 150%. The report also pointed out that the engineering-oriented value chain enterprises are currently the largest robot adopters in China, but with the gradual improvement of China's manufacturing automation, in the next two years, brand-oriented value chain enterprises, asset-oriented value chain enterprises and technology-oriented value chain enterprises There will be strong growth opportunities in terms of robot adoption.

Industry development growth leads the world

China's robot industry is in a period of great change. Domestic robot companies have grown from dozens of companies to thousands of them in recent years. It is reported that in 2016, robot sales in China accounted for more than 30% of global sales. China has become the world's largest industrial robot market for four consecutive years; GGII expects that China's industrial robot sales will maintain a growth rate of more than 20% in the next five years. From the current situation, Japan, South Korea, Europe and the United States have higher levels of automation, 3C industrial robots have high density; China's market demand is gradually released, and the two most demanding robots in the Chinese market in the future will come from the 3C industry and the new energy vehicle industry. The 3C industry will be the fastest growing industry for robots, with the largest demand and the most mature applications. In the future, new energy vehicles will be a larger pull.

While the speed of industrial development is accelerating, China's robots are also facing changes in technology and quality. This means that we can no longer rely solely on capacity and price competition, but to have a place in the international arena to create brand influence and quality. In this process, an effective way is mergers and acquisitions. The M&A layout can complement short-board and strong capabilities, and the acquisition of related advantages in the core components of robots and market segment integration can improve China's overall R&D level to a certain extent.

Market ceiling does not reach the upper limit

It is understood that industrial robots mainly include core parts production, body manufacturing, system integration and industrial applications. The reducer, servo motor and controller are the three core components of industrial robots. At present, ontology manufacturing and system integration are the strengths of domestic industrial robot companies. According to the relevant data of the Sui and Tang Dynasties Research Institute, among the core components of industrial robots, most of the well-known robotic body manufacturing enterprises in China have been able to produce controllers by themselves, but there is still a certain gap with the international level; while servo motors and reducers still rely heavily on imports. The high procurement cost has become one of the bottlenecks restricting the development of domestic robots.

Due to the failure to master the core technology, the gross profit of Chinese industrial robot companies is very low. At present, the core components are in the hands of overseas companies, the reducer accounts for 33% of the total cost, the servo motor accounts for 35%, and the controller and sensor account for 20%. The body manufacturing and system integration of Chinese enterprises are only about 10%. % profit. At this stage, we should concentrate on solving the quality problems of domestically produced basic hardware and key components. Even if we have a bearing, we can achieve world-class level, then the artificial intelligence robot business will definitely advance by leaps and bounds.

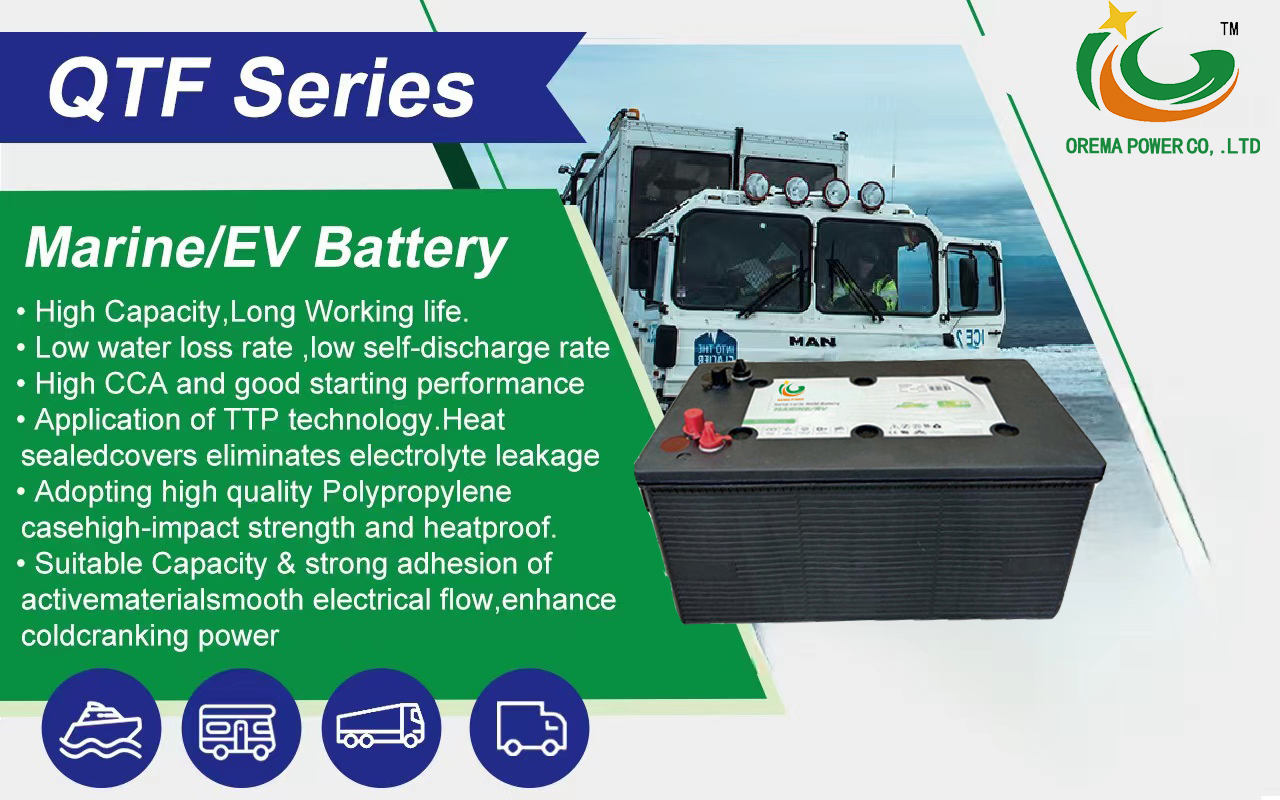

The OREMA EFB Series Marine/RV Battery features a high tin alloy plate with low conductive losses. As a kind of EFB Battery,OREMA EFB Series Marine/RV battery has excellent deep cycle discharge capability, can adapt to long working hours, while anti-impact performance upgrade, can be stable in extreme temperatures. Of course, this battery is also suitable for truck batteries.

In essence, the novel combination of EFB advancements and the acid mixing process in the OREMA EFB Marine/RV battery leverages the inherent dynamics of the vessel. This not only prevents acid layering, a common issue leading to performance degradation and battery failure, but also ensures a continuous high-performance level, extending the battery's longevity and reliability. Therefore, it is an excellent choice for marine and RV applications, promising both robust performance and durability.

The OREMA 12V EFB Marine/RV battery is a cutting-edge solution, synthesizing the latest innovations in Dual-Purpose Enhanced Flooded Battery (EFB) technology with a unique acid mixing system. This system ingeniously utilizes the vessel's natural movement to continuously circulate the acid throughout the battery. This consistent circulation acts as a strong defense against acid stratification, a primary reason for premature loss of battery performance and eventual failure.

12V EFB Marine/RV Battery,Deep Cycle Marine/RV Battery,12V Truck Battery,12v marine deep cycle battery

OREMA POWER CO., LTD. , https://www.oremapower.com

![<?echo $_SERVER['SERVER_NAME'];?>](/template/twentyseventeen/skin/images/header.jpg)